Land Rover Defender: Engine and Ancillaries - Installation

ENGINE AND ANCILLARIES - INGENIUM I4 2.0L PETROL

INSTALLATION

SPECIAL TOOL(S)

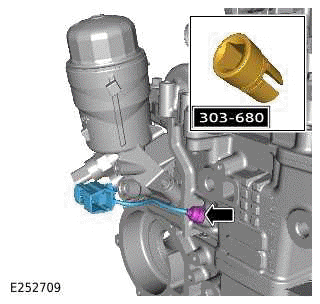

303-680

Socket, Cylinder Head Temperature Sensor

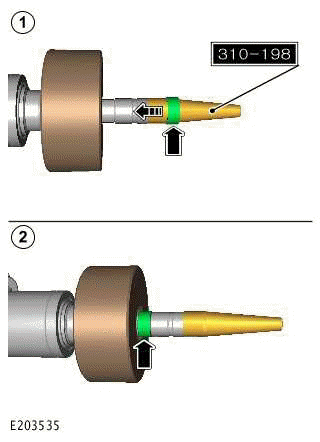

310-198

Installer, Teflon Seal

JLR-303-1630

Locking Tool, Crankshaft Pulley

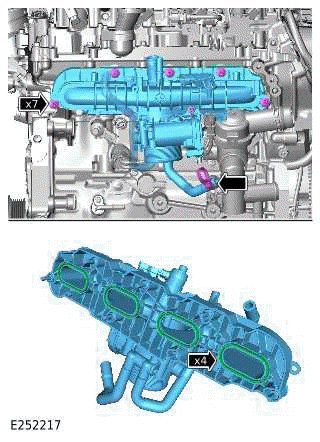

JLR-310-255

Guide pins threaded

JLR-310-256

Guide pins unthreaded

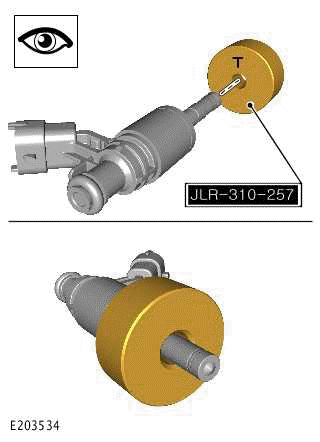

JLR-310-257

Teflon Seal Resize Tool

PART(S)

WARNING:

- Be prepared to collect escaping fuel.

- Be prepared to collect escaping coolant.

- Be prepared to collect escaping oil.

CAUTION: Before disconnecting any components, make sure the area is clean and free from foreign material. When disconnected all openings must be sealed.

NOTE:

- This procedure contains illustrations showing certain components removed to provide extra clarity.

- This procedure contains some variation in the illustrations depending on the vehicle specification, but the essential information is always correct.

1.

- Install the Noise, Vibration and Harshness (NVH) material.

- Install and tighten the bolt.

Torque: 11.5Nm

2.

- Install the NVH material.

- Install the clip.

3.

- Install the NVH material.

- Install the 4 clips.

4.

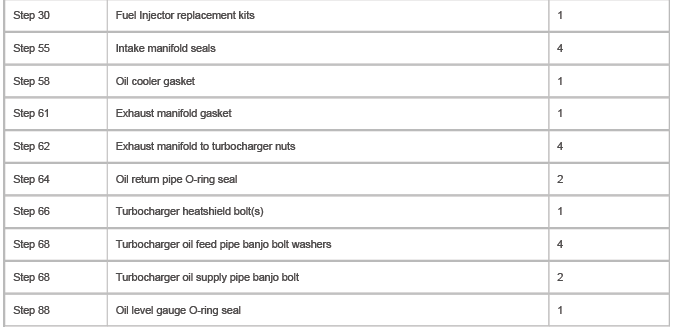

- Inspect the O-ring seal. Install a new O-ring seal if damaged or worn.

- Lubricate the O-ring seal with clean engine oil.

- Install the crankshaft pulley.

- Install the special tool.

Special Tool(s): JLR-303-1630

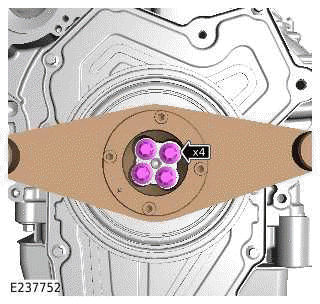

5.

Install and tighten the 4 bolts.

Torque

- Stage1: 37Nm

- Stage2: 90º

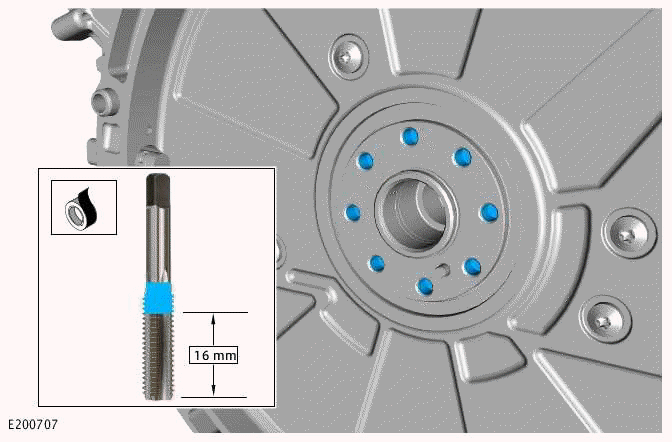

6.

NOTE: Do not insert the bottoming tap more than the depth of the threaded holes (16mm). Apply tape to the bottoming tap 16mm from the end as a visual guide.

- Use a suitable M10 x 1.0 mm tap to clean out the threads illustrated.

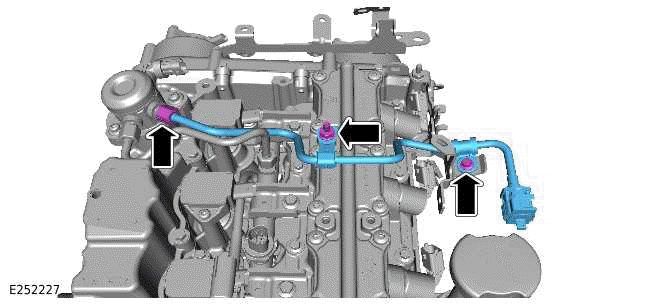

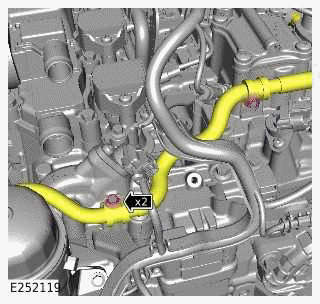

- Use a suitable cleaning solution to remove any foreign material from the threads.

7.

- Install the drive plate.

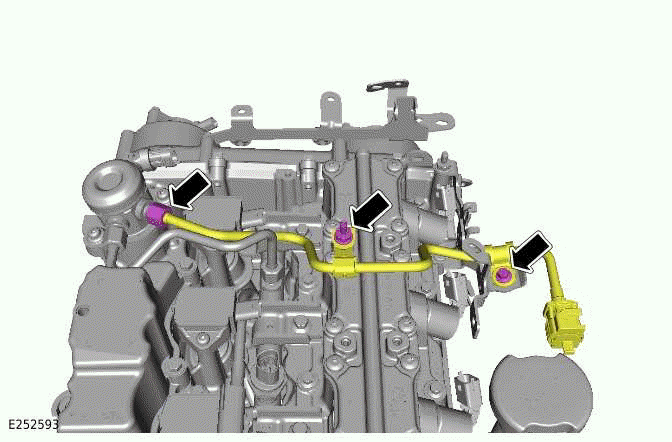

- Install, but do not fully tighten the 8 new bolts.

Renew Part: Drive plate bolts Quantity: 8.

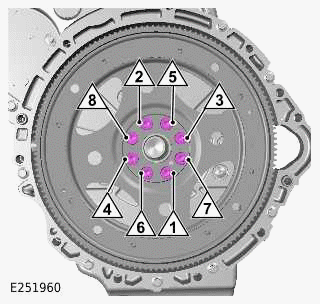

8.

Tighten the 8 bolts in the illustrated sequence.

Torque

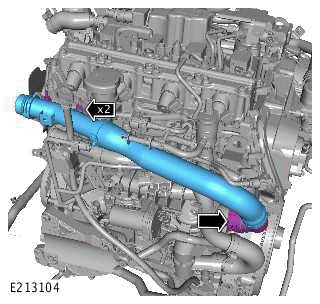

- Stage1: 30Nm

- Stage2: 120º

9. Remove the special tools.

Special Tool(s): JLR-303-1630

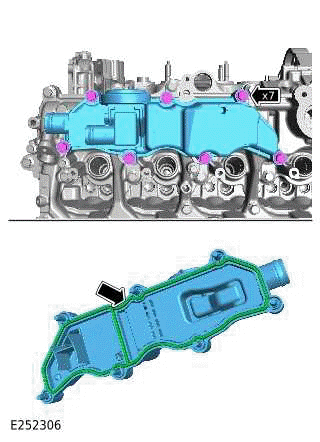

10.

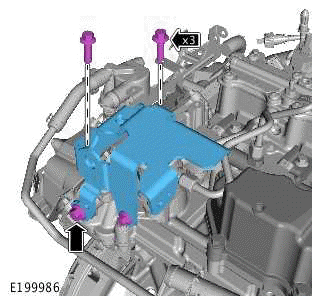

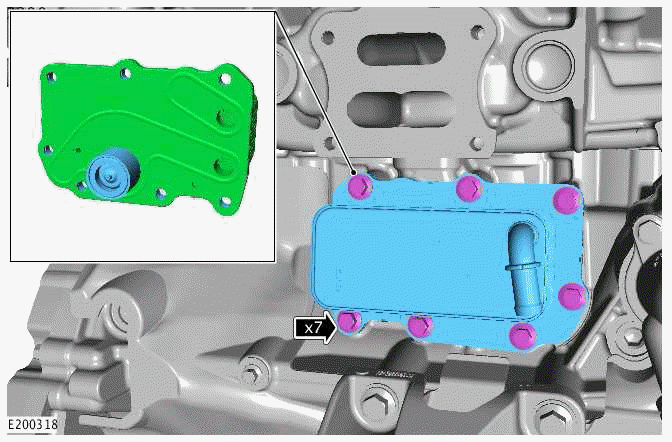

- Install a new gasket.

Renew Part: Engine Vent Oil Separator Seal(s) Quantity: 1.

- Install the engine vent oil separator.

- Install, but do not fully tighten the 7 bolts.

11.

Tighten the 7 bolts in the illustrated sequence.

Torque: 11.5Nm

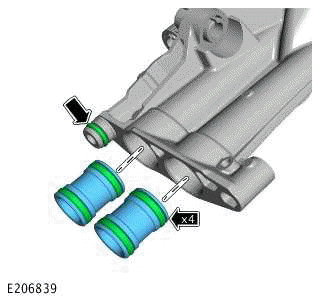

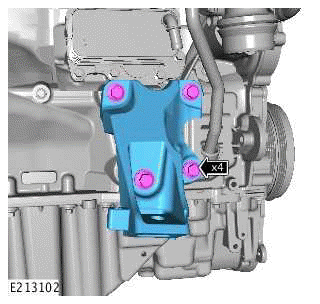

12.

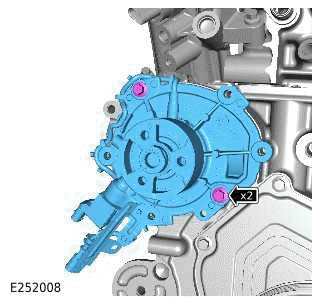

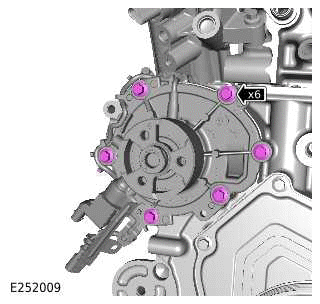

- Lubricate the O-ring seals with clean engine oil.

- Install 5 new O-ring seals.

Renew Part: Oil filter housing drain port O-ring seal Quantity: 1.

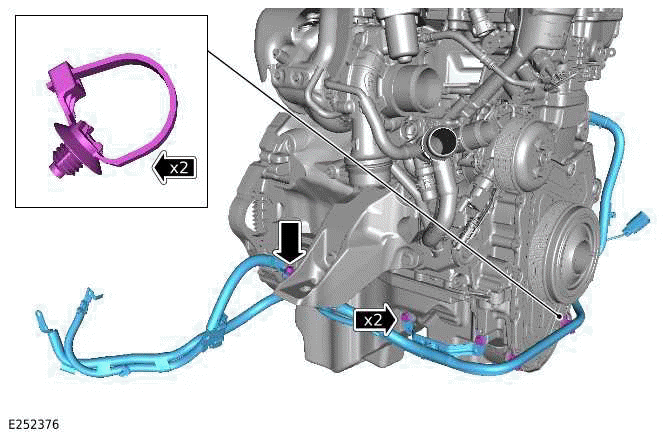

Renew Part: Oil filter housing inlet / outlet O-ring seals Quantity: 4.

13.

- Install the oil filter housing assembly.

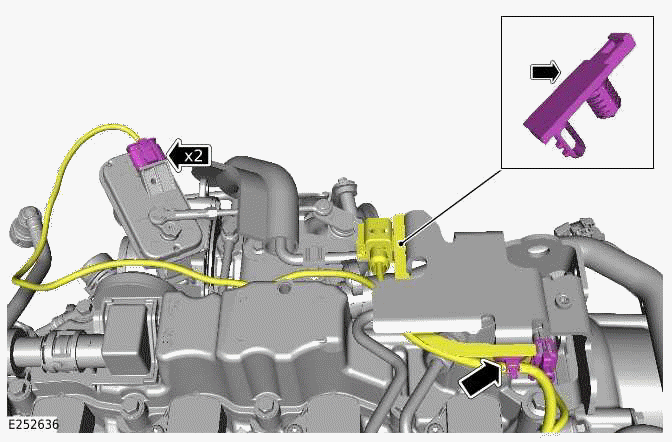

- Install and tighten the 3 bolts.

Torque: 11.5Nm

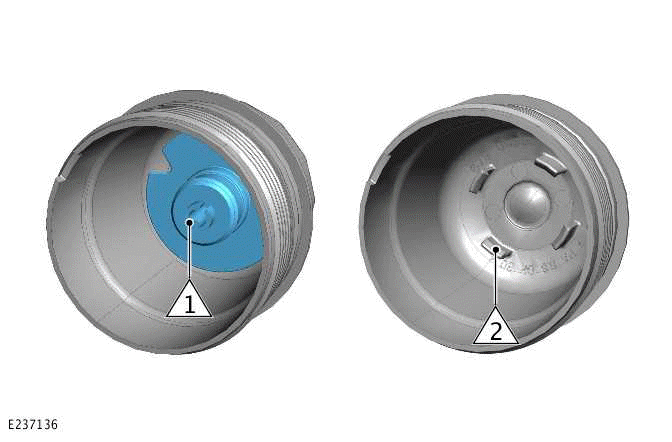

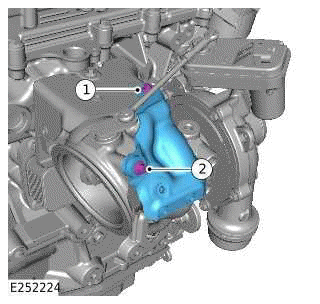

14.

Before installing the oil filter cap, check the by-pass valve (1) is installed and correctly secured on the locating tabs (2).

15.

- Install a new O-ring seal.

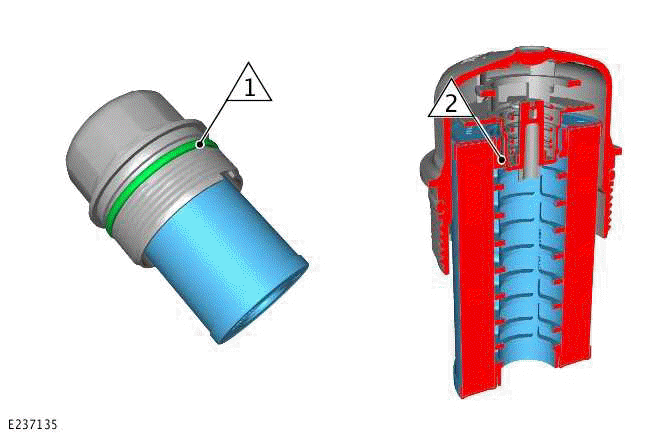

Renew Part: Oil filter and O-ring seal kit Quantity: 1.

- Install a new oil filter element.

- Lubricate the oil filter O-ring seal (1) with clean engine oil and install the oil filter element into the cap.

- Make sure the oil filter element is pushed correctly onto the bypass valve inside the oil filter cap (2).

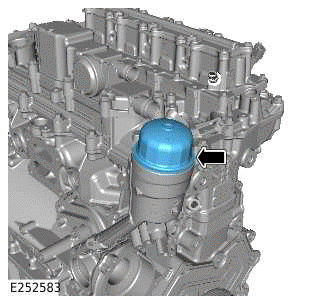

16.

Install and tighten the oil filter assembly.

Torque: 28Nm

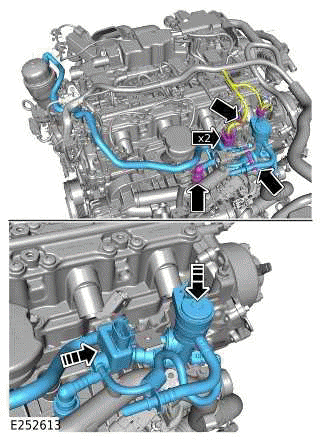

17.

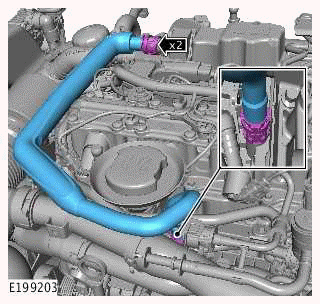

Use the special tool to install and tighten the new cylinder head temperature sensor.

Special Tool(s): 303-680

Renew Part: Cylinder head temperature sensor Quantity: 1.

Torque: 10.5Nm

18.

Install and tighten a new cylinder block temperature sensor.

Renew Part: Engine block temperature sensor Quantity: 1.

Torque: 10.5Nm

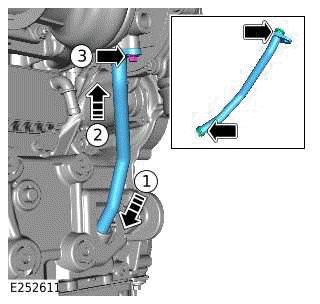

19.

- Inspect the O-ring seal. Remove and discard the O-ring seal if damaged or worn.

- Lubricate the O-ring seal with clean engine oil.

- Install the oil filler.

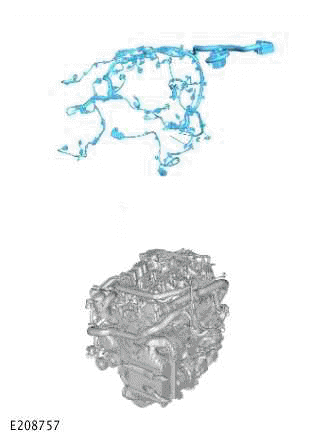

- Install and tighten the bolt.

Torque: 11.5Nm

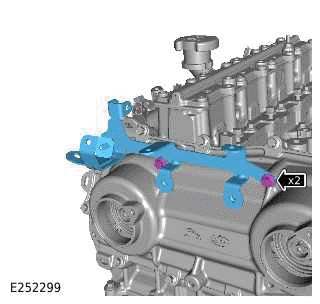

20.

- Install the bracket.

- Install and tighten the bolt.

Torque: 11.5Nm

21.

- Install the bracket.

- Install and tighten the 2 bolts.

Torque: 11.5Nm

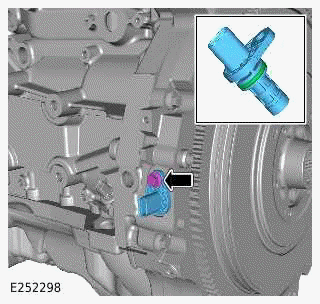

22.

- Inspect the O-ring seal. Install a new O-ring seal if damaged or worn.

- Lubricate the O-ring seal with clean engine oil.

- Install the Crankshaft Position Sensor (CKP) sensor.

- Install and tighten the bolt.

Torque: 8Nm

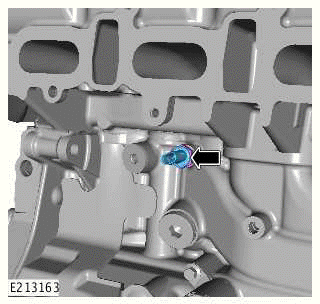

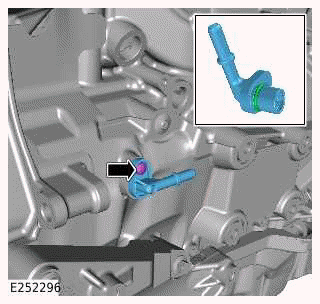

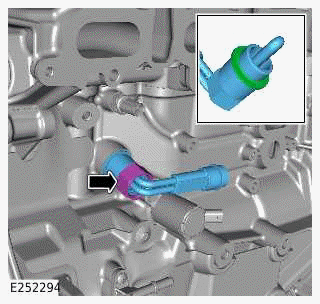

23.

- Inspect the O-ring seal. Install a new O-ring seal if damaged or worn.

- Lubricate the O-ring seal with clean engine oil.

- Install the vacuum pipe connector.

- Install and tighten the bolt.

Torque: 5Nm

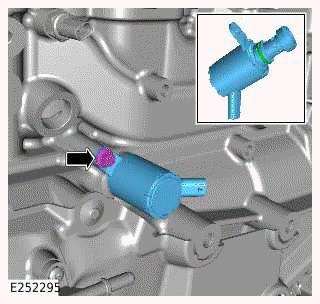

24.

- Inspect the O-ring seal. Install a new O-ring seal if damaged or worn.

- Lubricate the O-ring seal with clean engine oil.

- Install the piston cooling oil jet solenoid.

- Install and tighten the bolt.

Torque: 11.5Nm

25.

NOTE: If equipped.

- Install a new gasket.

Renew Part: Engine block heater manifold seal(s) Quantity: 1.

- Install and tighten the cylinder block heater.

Torque: 55Nm

26.

CAUTION: Make sure that the mating faces are clean and free of foreign material.

- Install the knock sensor to the position noted in the removal step.

- Install and tighten the bolt.

Torque: 20Nm

27.

CAUTION: Make sure that the mating faces are clean and free of foreign material.

- Install the knock sensor to the position noted in the removal step.

- Install and tighten the bolt.

Torque: 20Nm

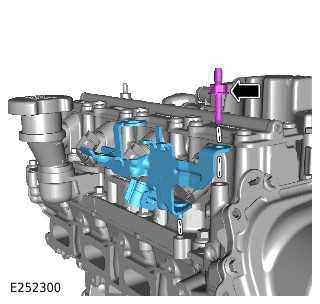

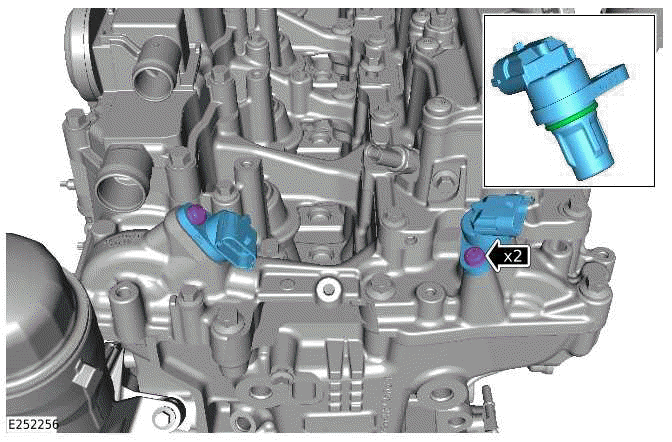

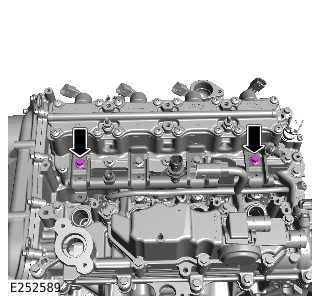

28.

- Inspect the O-ring seal. Install a new O-ring seal if damaged or worn.

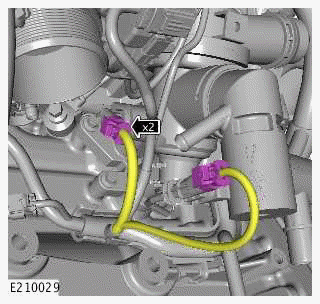

- Lubricate the 2 O-ring seals with clean engine oil.

- Install the 2 variable valve timing (VVT) solenoids.

- Install and tighten the 2 bolts.

Torque: 9Nm

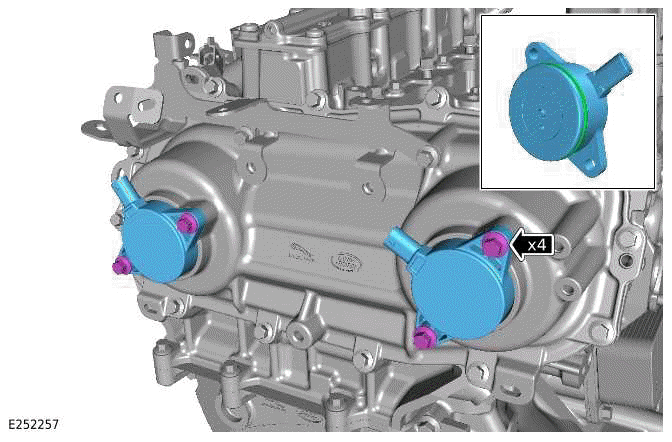

29.

- Inspect the 2 O-ring seals. Install a new O-ring seal if damaged or worn.

- Lubricate the 2 O-ring seals with clean engine oil.

- Install the 2 Camshaft Position Sensor (CMP) sensors.

- Install and tighten the 2 bolts.

Torque: 8Nm

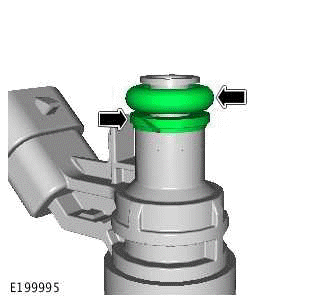

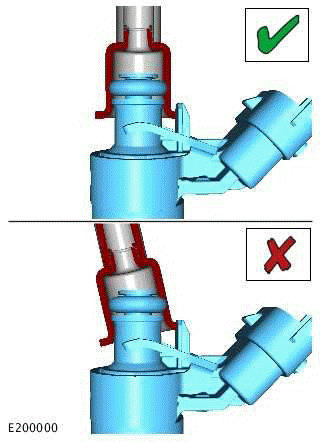

30.

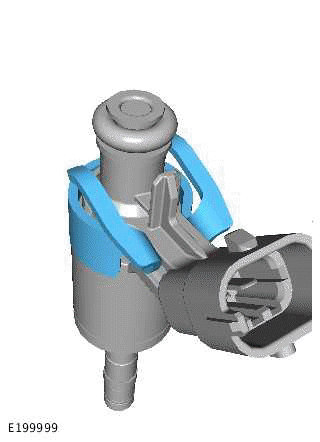

- Install a new fuel injector O-ring seal and washer.

Renew Part: Fuel Injector replacement kits Quantity: 1.

- Lubricate the O-ring seal with clean engine oil.

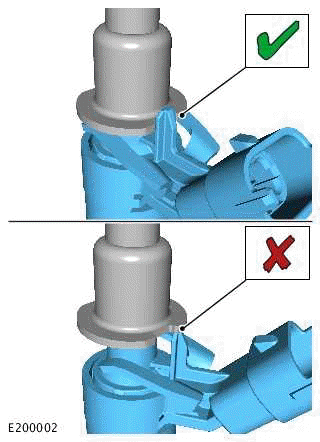

31.

Install the special tool to the fuel injector with the 'T' symbol towards the top of the fuel injector as illustrated.

Special Tool(s): JLR-310-257

32.

CAUTION: Make sure that the fuel injector Teflon seal groove is clean and free of foreign material.

Use the special tool 310-198 to install the Teflon seal to the fuel injector.

Special Tool(s): 310-198

33. Wait 2 minutes to allow the Teflon seal to recover its shape.

34.

- Make sure the Teflon seal is correctly installed.

- As illustrated, remove the special tool JLR-310-257 from the fuel injector to create the final shape of the Teflon seal.

35.

Install a new fuel injector spring clamp.

36. Repeat steps 30 to 35 for the 3 remaining fuel injectors.

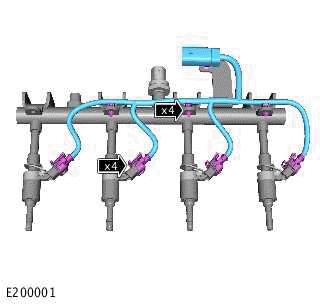

37.

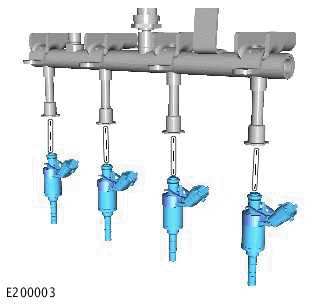

Install the 4 fuel injectors to the fuel rail.

38.

Make sure the fuel injectors are correctly aligned.

39.

Make sure the fuel injectors are correctly aligned.

40.

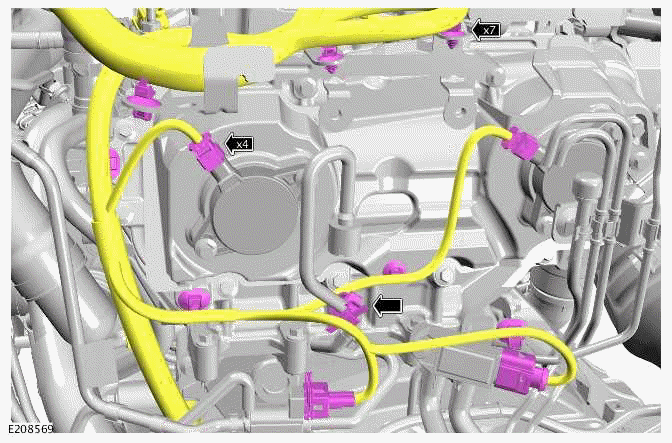

- Install the wiring harness.

- Connect the 4 electrical connectors.

- Install the 4 wiring harness clips.

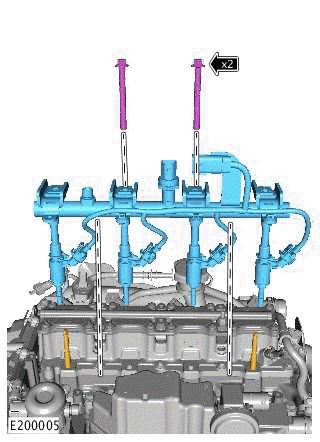

41.

Install the appropriate special tools. If a new cylinder head has not been installed then the special tool JLR-310-255 with the threaded section must be used. If a new cylinder head has been installed then the special tool JLR-310-256 without the threaded section must be used.

Special Tool(s): JLR-310-255, JLR-310-256

42.

CAUTION: Tighten the fuel rail bolts one turn at a time until the correct torque figure is achieved.

- Install the fuel rail and fuel injector assembly. Use the special tool guide pins to control the position.

- Install and tighten the 2 bolts.

Torque: 20Nm

43. Remove the special tools.

Special Tool(s): JLR-310-255, JLR-310-256

44.

CAUTION: Tighten the fuel rail bolts one turn at a time until the correct torque figure is achieved.

Install and tighten the 2 bolts.

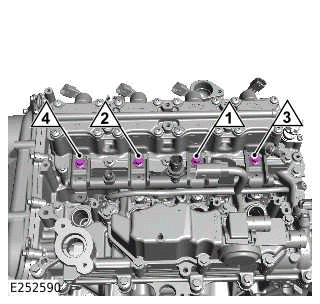

Torque: 20Nm

45.

Tighten the 4 bolts in the illustrated sequence.

Torque: 30Nm

46.

- Install the 4 ignition coils.

- Install and tighten the 4 bolts.

Torque: 8Nm

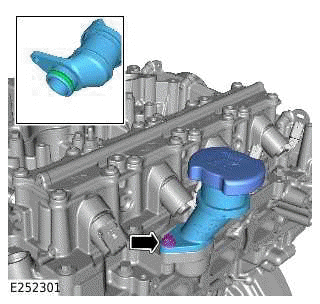

47.

- Lubricate the High Pressure (HP) fuel pump tappet with clean engine oil.

- Install the HP fuel pump tappet.

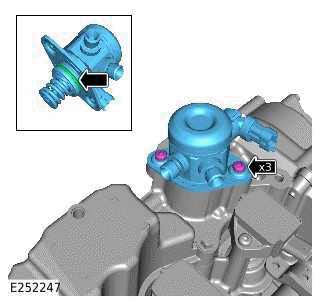

48.

CAUTION: Install the fuel pump evenly onto the camshaft cover surface by one turn on each bolt alternating until the required torque is achieved.

- Inspect the O-ring seal. Install a new O-ring seal if damaged or worn.

- Lubricate the O-ring seal with clean engine oil.

- Install the HP fuel pump.

- Install and tighten the 2 bolts.

Torque: 11.5Nm

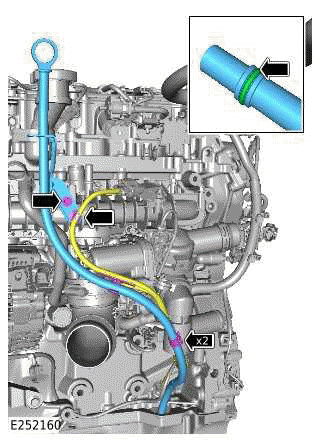

49.

- Install the HP fuel line.

- Tighten the 2 fuel line unions finger tight.

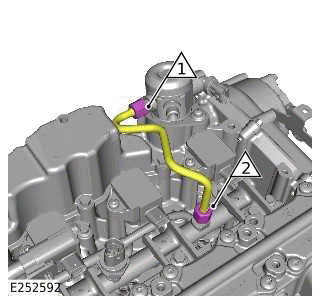

50.

- Tighten the 2 fuel line unions in the illustrated sequence.

Torque: 20Nm

- Wait for 30 seconds and recheck the final torque of the 2 fuel line

unions.

Torque: 20Nm

51.

- Install the HP fuel line.

- Tighten the fuel line union finger tight.

- Install and tighten the 2 bolts.

Torque

- Stage1: 11.5Nm

- Stage2: Loosen 90º

52.

- Tighten the fuel line union.

Torque: 20Nm

- Tighten the 2 bolts.

Torque: 11.5Nm

- Wait for 30 seconds and recheck the final torque of the fuel line union.

Torque: 20Nm

53.

- Install the bracket.

- Install and tighten the 4 bolts.

Torque

- M10: 47.5Nm

- M8: 25Nm

54.

- Inspect the gasket. Install a new gasket if damaged or worn.

- Install the thermostat housing.

- Install and tighten the 4 bolts.

Torque: 11.5Nm

55.

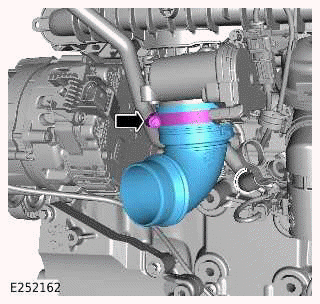

- Install the 4 new O-ring seals.

Renew Part: Intake manifold seals Quantity: 4.

- Install the intake manifold.

- Install, but do not fully tighten the 7 bolts.

- Connect the engine coolant hose and install the clamp.

56.

Tighten the 7 bolts in the illustrated sequence.

Torque: 11.5Nm

57.

- Inspect the O-ring seal. Install a new O-ring seal if damaged or worn.

- Install the engine coolant pipe.

- Install and tighten the 2 bolts.

Torque: 11.5Nm

58.

- Install a new gasket.

Renew Part: Oil cooler gasket Quantity: 1.

- Install the oil cooler.

- Install, but do not fully tighten the 7 bolts.

59.

Tighten the 7 bolts in the illustrated sequence.

Torque

- Stage1: 15Nm

- Stage2: 25Nm

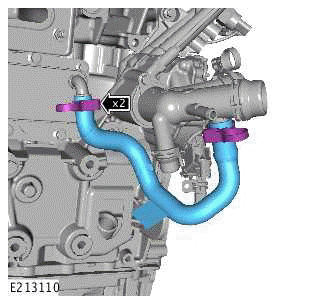

60.

- Install the engine coolant hose.

- Connect the 2 engine coolant hose clamps.

61.

Install a new exhaust manifold gasket.

Renew Part: Exhaust manifold gasket Quantity: 1.

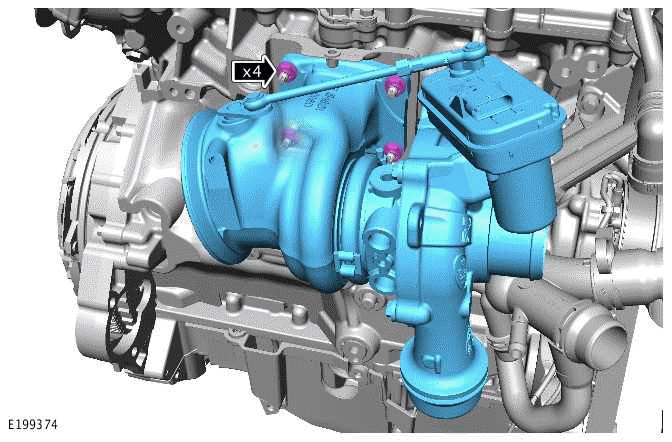

62.

- Install the turbocharger.

- Install, but do not fully tighten the 4 new nuts.

Renew Part: Exhaust manifold to turbocharger nuts Quantity: 4.

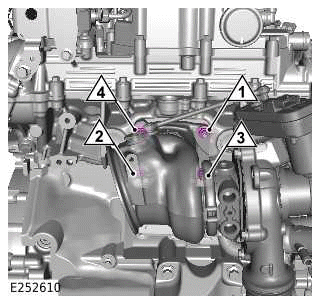

63.

Tighten the 4 nuts in the illustrated sequence.

Torque

- Stage1: 18Nm

- Stage2: 25Nm

64.

- Install 2 new O-ring seals.

Renew Part: Oil return pipe O-ring seal Quantity: 2.

- Install the turbocharger oil return pipe.

- Install and tighten the bolt.

Torque: 10.5Nm

65.

- Install the heatshield.

- Install and tighten the bolt.

Torque: 9Nm

66.

- Install the heatshield.

- Install and tighten the bolt (1).

Torque: 9Nm

- Install and tighten the new bolt (2).

Renew Part: Turbocharger heatshield bolt(s) Quantity: 1.

Torque: 9Nm

67.

- Install the heatshield.

- Install and tighten the 4 bolts.

Torque: 9Nm

68.

- Install the turbocharger oil feed pipe.

- Install 4 new sealing washers.

Renew Part: Turbocharger oil feed pipe banjo bolt washers Quantity: 4.

- Install and tighten the 2 new banjo bolts.

Renew Part: Turbocharger oil supply pipe banjo bolt Quantity: 2.

Torque: 18Nm

69.

- Install the bracket.

- Install and tighten the 4 bolts.

Torque: 60Nm

70.

- Install the engine coolant pump.

- Install and tighten the 2 bolts.

Torque: 6Nm

71.

- Install the remaining 4 bolts.

- Tighten the 6 bolts.

Torque: 11.5Nm

72.

NOTE: If required, use a suitable tool to prevent the pulley from rotating.

- Install the engine coolant pump pulley.

- Install and tighten the 3 bolts.

Torque: 25Nm

73.

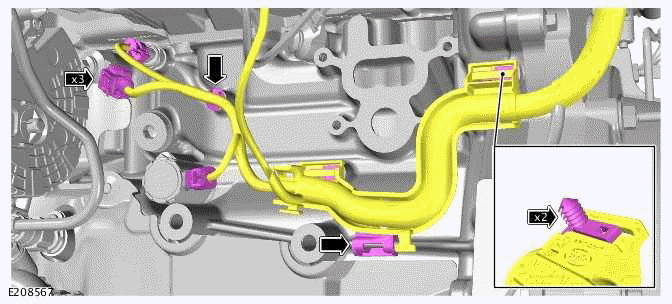

- Install the wiring harness.

- Install the 2 wiring harness clips.

- Install and tighten the 3 bolts.

Torque: 10Nm

74.

Install the wiring harness.

75.

- Connect the 2 electrical connectors.

- Install the 2 wiring harness clips.

76.

- Install and tighten the 2 nuts.

Torque: 10Nm

- Install the 3 wiring harness clips.

- Install and tighten the bolt.

Torque: 10Nm

- Connect the 11 electrical connectors.

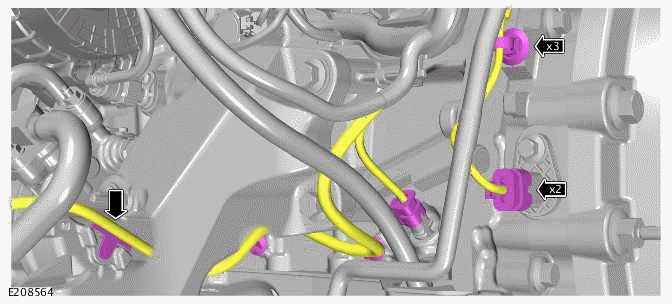

77.

- Install the 8 wiring harness clips.

- Connect the 4 electrical connectors.

78.

- Connect the 3 electrical connectors.

- Install the 4 wiring harness clips.

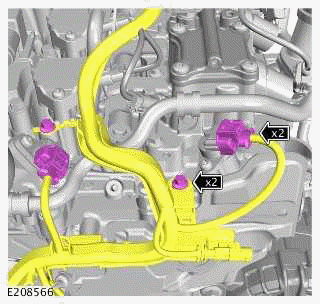

79.

- Connect the 2 electrical connectors.

- Install the wiring harness clip.

80.

- Connect the 2 electrical connectors.

- Install the 4 wiring harness clips.

81.

- Connect the 2 electrical connectors.

- Install and tighten the 2 bolts.

Torque: 10Nm

82.

- Connect the 4 electrical connectors.

- Install and tighten the 2 bolts.

- Install the 2 wiring harness clips.

83.

Connect the 2 electrical connectors.

84.

- Install the generator.

- Install and tighten the 2 bolts.

Torque: 47.5Nm

85.

- Install the wiring harness clip.

- Connect the electrical connector.

- Connect the startup battery positive cable.

- Install and tighten the nut.

Torque: 12Nm

- Reposition the cover.

86.

- Install the pipe.

- Tighten the clamp.

87.

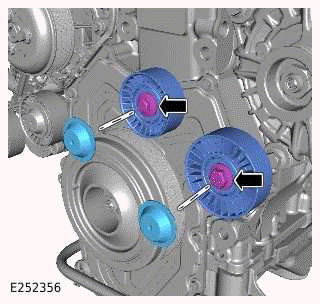

- Install the 2 pulleys.

- Install and tighten the 2 bolts.

Torque

- M10: 47.5Nm

- M8: 25Nm

- Install the 2 covers.

88.

- Install a new O-ring seal.

Renew Part: Oil level gauge O-ring seal Quantity: 1.

- Lubricate the O-ring seal with clean engine oil.

- Install the oil level gauge assembly.

- Install and tighten the bolt.

Torque: 7Nm

- Install the 3 wiring harness clips.

89.

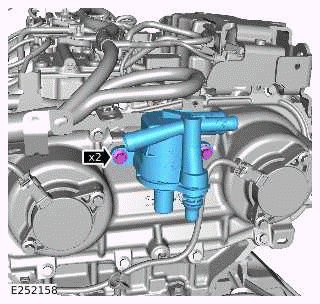

- Install the engine coolant degas separator.

- Install and tighten the 2 bolts.

Torque: 11.5Nm

90.

- Inspect the O-ring seal. Install a new O-ring seal if damaged or worn.

- Install the engine coolant hose.

- Connect the engine coolant hose and install the clamp.

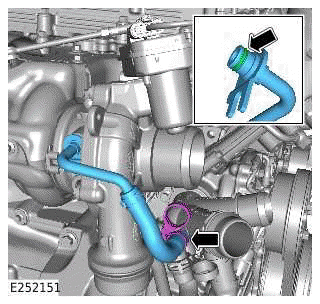

91.

- Inspect the O-ring seal. Install a new O-ring seal if damaged or worn.

- Install the engine coolant hose.

- Install and tighten the bolt.

Torque: 11.5Nm

- Connect the engine coolant hose and install the clamp.

- Install the clip.

92.

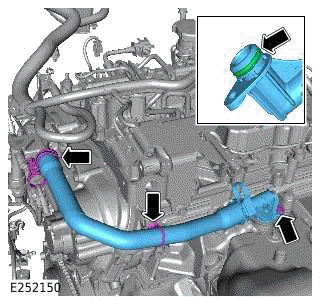

- Inspect the O-ring seal. Install a new O-ring seal if damaged or worn.

- Install the engine coolant hose assembly.

- Install and tighten the 3 bolts.

Torque: 11.5Nm

- Connect the engine coolant hose and install the clamp.

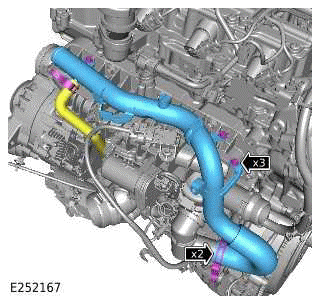

93.

- Install the engine coolant hose.

- Connect the 2 engine coolant hoses and install the 2 clamps.

Install and tighten the 3 bolts.

- Torque: 7Nm

94.

- Install the purge valve assembly.

- Connect the breather pipe connector.

- Install the 2 clips.

- Connect the 2 electrical connectors.

95.

Install and tighten the 2 bolts.

Torque: 11.5Nm

96.

- Install the vacuum harness.

- Install the 5 vacuum harness clips.

- Connect the vacuum pipe connector.

97.

- Install the engine coolant hose.

- Connect the engine coolant hose.

- Install and tighten the 2 bolts.

Torque: 11.5Nm

98.

- Install the breather pipe.

- Connect the 2 breather pipe connectors.

99.

- Install the engine coolant pipe.

- Install the clip.

- Connect the engine coolant pipe.

100.

- Install the engine coolant pipe.

- Connect the 2 engine coolant hoses and install the 2 clamps.

- Install and tighten the 2 bolts.

Torque: 25Nm

- Install the wiring harness clip.

101.

- Install the NVH material.

- Install the 3 clips.

102. Install the engine assembly.

103. Fill the engine with clean engine oil.