Land Rover Defender: Upper Timing Cover

REMOVAL AND INSTALLATION

PART(S)

REMOVAL

WARNING: Be prepared to collect escaping coolant.

CAUTION: Before disconnecting any components, make sure the area is clean and free from foreign material. When disconnected all openings must be sealed.

NOTES:

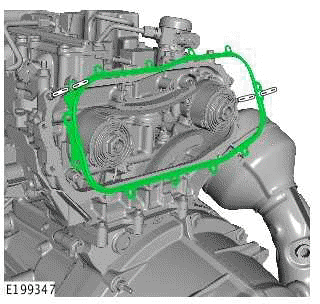

- This procedure contains some variation in the illustrations depending on the vehicle specification, but the essential information is always correct.

- This procedure contains illustrations showing certain components removed to provide extra clarity.

1. Raise and support the vehicle on a suitable 2 post lift.

2. Disconnect the startup battery ground cable.

3. Partially drain the cooling system.

4. Remove the engine cover.

5. Remove the secondary bulkhead center panel.

6.

- Release the breather pipe from the clip.

- Reposition the breather pipe away from the bracket.

- Remove the bolt.

- Remove the bracket.

7.

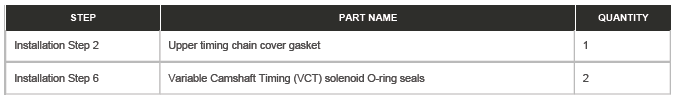

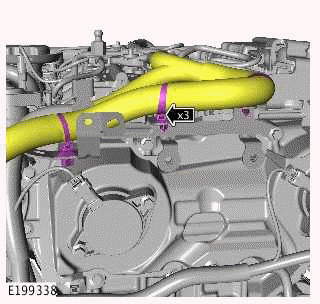

Disconnect the 3 coolant hoses.

8.

- Remove the bolt.

- Release the 2 hose clamps.

- Disconnect the 2 coolant hoses.

9.

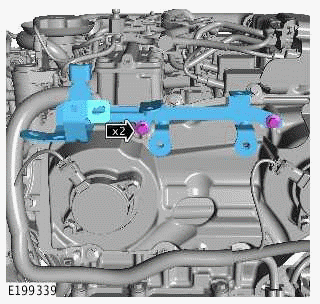

- Remove the 2 bolts.

- Remove the engine coolant degas separator.

10.

- Release the 3 wiring harness clips.

- Reposition the engine wiring harness away from the bracket.

11.

- Remove the 2 bolts.

- Remove the wiring harness bracket.

12.

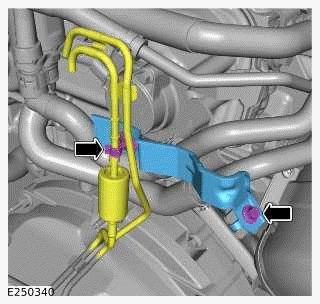

Disconnect the 2 electrical connectors from the Variable Camshaft Timing (VCT) solenoids.

13.

- Release the 3 wiring harness clips.

- Reposition the engine wiring harness away from the upper timing cover.

14.

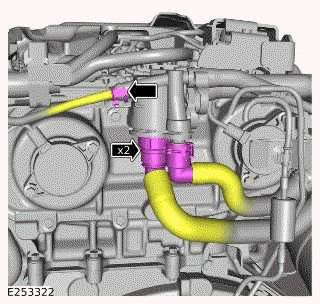

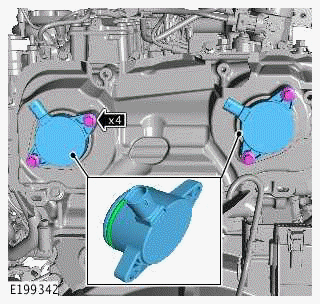

- Remove the 4 bolts.

- Remove the 2 VCT solenoids.

- Remove and discard the 2 O-ring seals.

15.

NOTE: If equipped.

Remove the Noise, Vibration and Harshness (NVH) material.

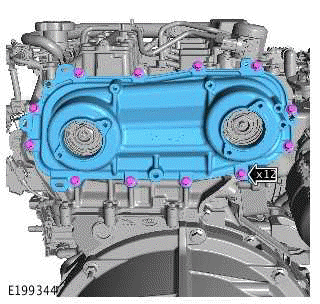

16.

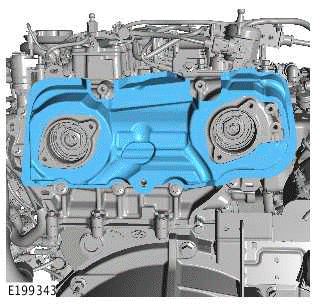

- Remove the 12 bolts.

- Remove the upper timing cover.

17.

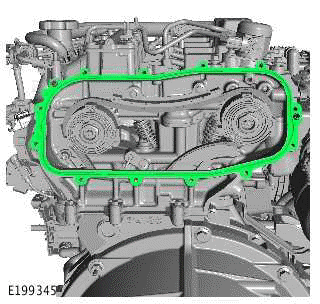

Remove and discard the gasket.

INSTALLATION

1.

CAUTION: Make sure that all traces of the old sealant are removed from the mating surfaces.

- Apply a 3 mm diameter bead of sealant to the area illustrated.

2.

Install the new gasket.

3.

- Install the upper timing cover.

Torque

- Stage1: 13.5Nm

- Stage2: Loosen: 180º

- Stage3: 13.5Nm

4.

NOTE: If equipped.

Install the NVH material.

5.

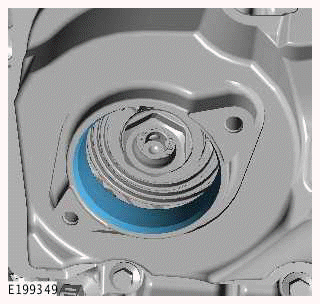

Lubricate the VCT solenoid bores with clean oil.

6.

CAUTION: Make sure that the area around the component is clean and free of foreign material.

- Install the 2 new O-ring seals.

Renew Part: Variable Camshaft Timing (VCT) solenoid O-ring seals Quantity: 2.

- Install the 2 VCT solenoids.

- Install and tighten the 4 bolts.

Torque: 9Nm

7.

- Reposition the engine wiring harness in the correct location.

- Install the 3 wiring harness clips.

- Connect the 2 electrical connectors to the VCT solenoids.

8.

- Install the wiring harness bracket.

- Install and tighten the 2 bolts.

Torque: 10Nm

- Reposition the engine wiring harness in the correct location.

- Install the 3 wiring harness clips.

9.

- Install the engine coolant degas separator.

- Install and tighten the 2 bolts.

Torque: 10Nm

10.

- Connect the 5 coolant hoses to the degas separator.

- Install the 2 hose clamps.

- Install and tighten the bolt.

Torque: 10Nm

11.

- Install the bracket.

- Install and tighten the bolt.

Torque: 10Nm

- Install the breather pipe to the clip.

12. Install the secondary bulkhead center panel.

13. Install the engine cover.

14. Vacuum fill the cooling system.

15. Connect the startup battery ground cable.