Land Rover Defender: Air Conditioning (A/C) System Precautions

The A/C system contains fluids and components which could be potentially hazardous to the service engineer or the environment if not serviced and handled correctly. The following guidelines are intended to alert the service engineer to potential sources of danger and emphasise the importance of ensuring the integrity of the A/C operating conditions and components installed to the vehicle.

Where necessary, additional specific precautions are detailed in the relevant sections of this Manual and also in the Health and Safety Section. These precautions must be referred to prior to commencing repair operations.

The refrigerant used in the A/C system is HC-134a (Hydrofluorocarbon) R134a.

WARNINGS:

- Servicing must only be carried out by personnel familiar with both the vehicle system and the charging and testing equipment. All operations must be carried out in a well ventilated area away from open flame and heat sources.

- R134a is a hazardous liquid and when handled incorrectly can cause serious injury. Suitable protective clothing, consisting of face protection, heat proof gloves, rubber boots and rubber apron or waterproof overalls, must be worn when carrying out operations on the A/C system.

Remedial actions

WARNING: Due to its low evaporating temperature, R134a must be handled with care. R134a splashed on any part of the body will cause immediate freezing of that area. Also, refrigerant cylinders and replenishment trolleys when discharging will freeze skin to them if contact is made.

If an accident involving R134a should occur, conduct the following remedial actions:

- If liquid R134a enters the eye, do not rub it. Gently run large quantities of eye wash over affected eye to raise the temperature. If an eye wash is not available, cool, clean water may be used to flush the eye. After rinsing, cover the eye with a clean pad and seek immediate medical attention.

- If liquid R134a is splashed onto the skin, run large quantities of water over the affected area to raise the temperature. Implement the same action if the skin comes in contact with discharging cylinders. Wrap the contaminated body parts in blankets (or similar materials) and seek immediate medical attention.

- If the debilitating effects of inhalation of R134a vapour are suspected, seek fresh air. If the affected person is unconscious, move them away from the contaminated area to fresh air and apply artificial respiration and/or oxygen and seek immediate medical attention.

Service precautions

Observe the following precautions when handling components used in the system:

- A/C units must not be lifted by their hoses, pipes or capillary lines.

- Hoses and lines must not be subjected to any twist or stress; the efficiency of the system will be impaired by kinks or restrictions. Make sure that hoses are correctly positioned before tightening couplings, and make sure that all clips and supports are utilised.

- Flexible hoses should not be positioned closer than 100 mm (4.0 in) to the exhaust manifold unless protected by heat shielding.

- Completed assemblies must be checked for refrigeration lines touching metal panels. Any direct contact of components and panels may transmit noise and so must be eliminated.

- The appropriate torque wrench must be used when tightening refrigerant connections to the stipulated value. An additional spanner must be used to hold the union to prevent twisting of the pipe when tightening connections.

- Before connecting any hose or pipe, make sure that refrigerant oil is applied to the seat of the new O-rings, BUT NOT to the threads of the connection.

- All protective plugs or caps must remain in place in the component until immediately prior to connection.

- Make sure components are at room temperature before uncapping/unplugging, to prevent condensation of moisture from the air that enters it.

- When disconnecting, immediately plug or cap all pipes to prevent ingress of dirt and moisture into the system.

- Components must not remain uncapped/unplugged, if a system has been left uncapped/unplugged for 24 hours or longer, a new receiver/drier must be installed.

- The receiver/drier contains desiccant which absorbs moisture. It must be positively sealed at all times. A receiver /drier that has been left uncapped for longer than 24 hours must not be used; install a new unit.

- The receiver/drier should be the last component connected to the system to make sure optimum dehydration and maximum moisture protection of the system.

- Use alcohol and a clean lint-free cloth to clean dirty connections.

- Make sure that all new parts installed are marked for use with R134a.

- When a major repair has been completed, a leak test should be conducted; refer to the Repairs Section of this manual for the correct procedure.

Refrigerant oil

CAUTION: Refrigerant oil (ND-8 PAG) easily absorbs water and must not be stored for long periods. Do not pour unused refrigerant oil back into the container. Always use an approved refrigerant oil.

When replacing components in the system, drain the refrigerant oil from the component being replaced into a graduated container. On assembly, add the quantity of refrigerant oil drained to the new component - See Compressor Replacement in this Section.

A/C Compressor

A new compressor is sealed and pressurised with Nitrogen gas. When installing a new compressor, slowly release the sealing cap; gas pressure should be heard to vent as the seal is broken.

CAUTION: A new compressor should always be sealed and should be pressurised with nitrogen gas. To avoid possible oil loss, release the sealing cap(s) slowly. Do not remove the cap(s) until immediately prior to connecting the pipes to the compressor.

Rapid refrigerant discharge

If the A/C system is damaged as a result of an accident and the system is punctured, the refrigerant will discharge rapidly. The rapid discharge of refrigerant will also result in the loss of most of the oil from the system. The compressor must be removed and all the remaining oil in the compressor drained and refilled as instructed in the air conditioning section of this manual.

Precautions for refrigerant recovery, recycling and recharging

When the A/C system is recharged, any existing refrigerant is first recovered from the system and recycled. The system is then charged with the required weight of refrigerant and volume of refrigerant oil.

WARNING: Refrigerant must always be recycled before re-use to make sure that the purity of the refrigerant is high enough for safe use in the system. Recycling should always be carried out with equipment which is design certified by Underwriter Laboratory Inc. for compliance with SAE J1991. Other equipment may not recycle refrigerant to the required level of purity.

CAUTIONS:

- A R134a Refrigerant Recovery Recycling Recharging Station must not be used with any other type of refrigerant. Refrigerant R134a from domestic and commercial sources must not be used in motor vehicle systems.

- The system must be evacuated immediately before recharging commences. Delay between evacuation and recharging is not permitted.

A/C Compressor Replacement

A new compressor is supplied filled with a full charge (X cm³) of refrigerant oil.

A calculated quantity of oil must be drained from the new compressor before installation. To calculate the quantity of oil to be drained:

- Remove the drain plug from the old compressor.

- Invert the compressor and gravity drain the oil into a calibrated measuring cylinder. Rotate the compressor clutch to make sure the compressor is completely drained.

- Note the quantity of oil drained (Y cm³).

- Calculate the quantity of oil to be drained from the new compressor using the following formula: X cm³ - (Y cm³ + 20 cm³) = Q cm³

- Remove the drain plug from the new compressor and drain Q cm³ of oil. Install and tighten the compressor drain plug.

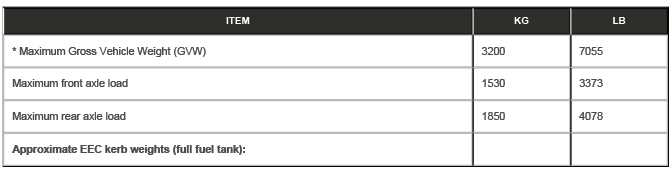

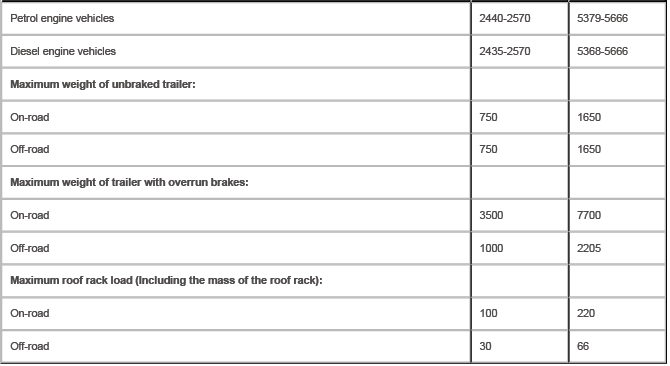

Vehicle Weights

* Weight quoted is the maximum weight possible for vehicles in this model range; weights may be less for certain variants depending upon trim level, territorial requirements etc.

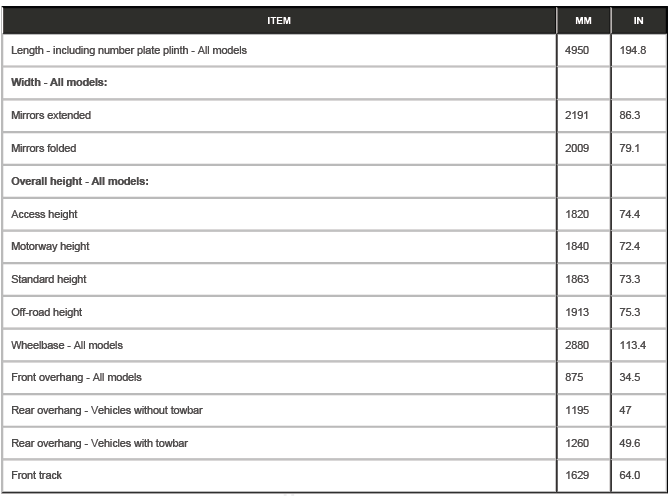

Vehicle Dimensions