Land Rover Defender: Supplemental Restraint System (SRS) Precautions

WARNING: Do not install rear facing child seats in the front passenger seat.

The SRS contains components which are potentially hazardous to service personnel if not handled correctly. The following guidelines and precautions are intended to alert personnel to potential sources of danger and emphasise the importance of ensuring the integrity of the SRS components installed to the vehicle.

WARNING: The following precautions MUST be adhered to when working on the SRS:

- The correct procedures must always be used when working on SRS components.

- Persons working on the SRS must be fully trained and have been issued with the safety guidelines.

- The air bag modules contain extremely flammable and hazardous compounds. Contact with water, acids or heavy metals may produce harmful or explosive results. Do not dismantle, incinerate or bring into contact with electricity before the unit has been deployed.

- Always replace a safety belt assembly that has withstood the strain of a severe vehicle impact or if the webbing shows signs of fraying.

- Allow a period of 1 minute to elapse after disconnecting the battery before undertaking any work on the SRS.

- Always disconnect the vehicle battery before carrying out any electric welding on a vehicle installed with SRS.

CAUTION: Do not expose air bag modules or safety belt pre-tensioners to temperatures exceeding 85º C (185º F).

It should be noted that these precautions are not restricted to operations performed when servicing the SRS. The same care should be exercised when working on ancillary systems and components located in the vicinity of SRS components; these include but are not limited to:

- Driver air bag, clockspring.

- Passenger air bag.

- Side Air Curtains - front and rear.

- Safety belt pre-tensioners.

- SRS harnesses, link leads and connectors.

Making the system safe

Before working on or in the vicinity of SRS components, make sure the system is rendered safe by performing the following operations:

- Remove the ignition key.

- Disconnect the battery, earth lead first.

- Wait 1 minute for the SRS power circuit to discharge before commencing work.

NOTE: The SRS uses energy reserve capacitors to keep the system active in the event of electrical supply failure under crash conditions. It is necessary to allow the capacitors sufficient time to discharge (1 minute) in order to avoid the risk of accidental deployment.

Installation

In order to make sure system integrity, it is essential that the SRS system is regularly checked and maintained so that it is ready for effective operation in the event of a collision. Carefully inspect SRS components before installation. Do not install a part that shows signs of being dropped or improperly handled, such as dents, cracks or deformation.

WARNING: The integrity of the SRS is critical for safety reasons. Make sure the following precautions are always adhered to:

- Do not install accessories or other objects to trim panels which

cover air bags.

Never install used SRS components from another vehicle or attempt to repair an SRS component.

- When repairing an SRS system, only use genuine new parts.

- Never apply electrical power to an SRS component unless instructed to do so as part of an approved test procedure.

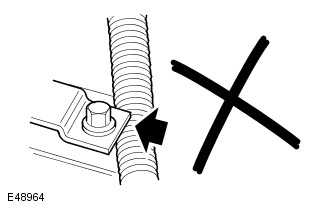

- Special fixings are necessary for installing an air bag module - do not use other fixings and make sure that all fixings are tightened to the correct torque.

- Always use new fixings when replacing an SRS component.

CAUTIONS:

- Take care not to trap air bag modules when installing interior trim components.

- Make sure SRS components are not contaminated by oil or grease.

NOTES:

- Following safety belt pre-tensioner deployment, the safety belts can still be used as conventional safety belts but will need to be replaced as soon as possible to make sure full SRS protection.

- If the SRS components are to be replaced, the part number/bar code of the new unit must be recorded.

SRS component testing precautions

The SRS components are triggered using relatively low operating currents, always adhere to the following:

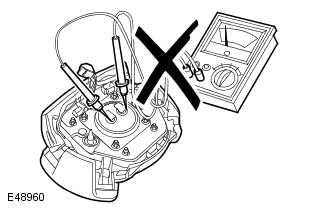

WARNING: Never use a multimeter or other general purpose equipment on SRS components. Use only Jaguar Land Rover diagnostic equipment to diagnose system faults.

WARNING: Do not use electrical test equipment on the SRS harness while it is connected to any of the SRS components, it may cause accidental deployment and injury.

Handling and storage

Always observe the following precautions when handling SRS components:

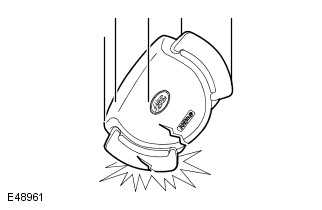

- Never drop an SRS component. The air bag diagnostic control unit is a particularly shock sensitive device and must be handled with extreme care. Air bag modules and safety belt pre-tensioners could deploy if subjected to a strong shock.

- Never wrap your arms around an air bag module. If a module has to be carried, hold it by the cover with the cover uppermost and the base away from your body.

- Never transport air bag modules or safety belt pre-tensioners in the passenger compartment of a vehicle. Always use the luggage compartment of the vehicle for carrying air bag modules and safety belt pre-tensioner units.

- Never attach anything to an air bag cover or any trim component covering an air bag module. Do not allow anything to rest on top of an air bag module.

- Always keep components cool, dry and free from contamination.

- Never apply grease or cleaning solvents to safety belt pre-tensioner units, component failure could result.

- Always store an air bag module with the deployment side uppermost. If it is stored deployment side down, accidental deployment will propel the air bag module with sufficient force to cause serious injury.

- Keep new air bag modules in their original packaging until just prior to installation. Place the old module in the empty packaging for carriage.

WARNINGS:

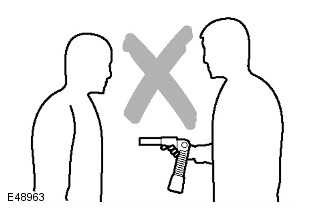

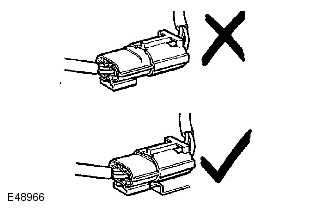

- When handling any SRS component, hold by the gas generator housing, DO NOT hold by the air bag. Do not wrap the thumb around the gas generator while holding. Do not drape air bag over shoulder or around neck. For safety belt buckle type pre-tensioners, hold by the piston tube, with the open end of the piston tube pointing towards the ground and the buckle facing away from your body. Do not cover the end of the piston tube. DO NOT hold buckle type pre-tensioners by the bracket assembly or cable. Never point the piston tube towards your body or other people.

- Air bag modules and safety belt pre-tensioners are classed as explosive devices. For overnight and longer term storage, they must be stored in a secure steel cabinet which has been approved as suitable for the purpose and has been registered with the local authority.

- Store air bag modules or safety belt pre-tensioners in a designated storage area. If there is no designated storage area available, store in the locked luggage compartment of the vehicle and inform the workshop supervisor.

CAUTION: Improper handling or storage can internally damage the air bag module making it inoperative. If you suspect the air bag module has been damaged, install a new module and refer to the deployment/disposal procedures for disposal of the damaged module.

SRS harness and connectors

Always observe the following precautions with regards to SRS system electrical wiring:

- SRS firing circuit wiring may only be repaired using the approved repair kit in accordance with the correct instructions.

- Never install electrical equipment such as a mobile telephone, two-way radio or in-car entertainment system in such a way that it could generate electrical interference in the air bag harness. Seek specialist advice when installing such equipment.

NOTE: SRS wiring can be identified by a special yellow outer sleeve protecting the wires (black with yellow stripe protective coverings are sometimes used).

WARNING: Always make sure SRS wiring is routed correctly. Be careful to avoid trapping or pinching the SRS wiring.

WARNING: Do not leave the connectors hanging loose or allow SRS components to hang from their harnesses. Look for possible chafing points.

Impact sensors - inspection

After any degree of side or frontal body damage, inspect the impact sensors. Replace a sensor if there is any sign of damage.

CAUTION: Take extra care when painting or carrying out bodywork repairs in the vicinity of the impact sensors. Avoid direct exposure of the impact sensors or link harnesses to heat guns, welding or spraying equipment. Take care not to damage sensor or harness when reinstalling components.

Clockspring

CAUTION: Always follow the procedure for installing and checking the clockspring as instructed in the SRS repairs section. Comply with all safety and installation procedures to make sure the system functions correctly.

Observe the following precautions:

- Do not unlock and rotate the clockspring when it is removed from the vehicle.

- Do not turn the road wheels when the clockspring is removed from the vehicle.

- Always make sure the clockspring is removed and installed in its central position and with the front road wheels in the straight ahead position - refer to SRS repair section for the correct removal and installation procedure.

- If a new clockspring is being installed, make sure the locking tab holding the spring's rotational position is not broken; units with a broken locking tab must not be used.