Land Rover Defender: Cabin Comfort Climate Control System

DIAGNOSIS AND TESTING

PRINCIPLES OF OPERATION

For a detailed description of the Climate Control System, refer to the relevant Description and Operation section in the workshop manual.

Air Distribution and Filtering (Description and Operation), Heating and Ventilation (Description and Operation), Air Conditioning (Description and Operation), Control Components (Description and Operation).

INSPECTION AND VERIFICATION

WARNING: Servicing must be completed by personnel familiar with both vehicle system and the charging and testing equipment. All operations must be completed in a well ventilated area away from open flame and heat sources.

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

NOTES:

- If a control module or a component at fault and the vehicle remains under manufacturer warranty, refer to the Warranty Policy and Procedures manual, or determine if any prior approval program is in operation, prior to the installation of a new module/component.

- When performing voltage or resistance tests, always use a digital multimeter that has the resolution ability to view 3 decimal places. For example, on the 2 volts range can measure 1mV or 2 K Ohm range can measure 1 Ohm. When testing resistance always take the resistance of the digital multimeter leads into account.

- Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

- Verify the customer concern

- Visually inspect for obvious signs of damage and system integrity

Visual Inspection

- If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to the next step

- If the cause is not visually evident, verify the symptom and refer to the Symptom Chart, alternatively check for Diagnostic Trouble Code(s) and refer to the Diagnostic Trouble Code(s) (DTC) Index

- Check the JLR claims submission system for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific customer complaint and complete the recommendations as required

HVAC CONTROL SYSTEM SENSOR RESISTANCE VALUES

SYMPTOM CHART - AUTO CLIMATE CONTROL

SYMPTOM CHART - MANUAL CLIMATE CONTROL

PINPOINT TESTS

PINPOINT TEST A : PASSENGER COMPARTMENT TEMPERATURE SENSOR CHECKS

PINPOINT TESTS

PINPOINT TEST B : DUCT AIR TEMPERATURE SENSOR CHECKS

PINPOINT TESTS

PINPOINT TEST C : RECIRCULATION INLET DOOR POSITION

PINPOINT TEST C : RECIRCULATION INLET DOOR POSITION

FRONT TO REAR HVAC SYSTEM VENT IMBALANCE TEST

Diagnostic Procedure

Vent temperature difference test

NOTES:

- If the customer cannot set a constant comfortable temperature and the air blowing through the rear air vents is noticeably hotter than air blowing through other vents, continue with this diagnostic procedure

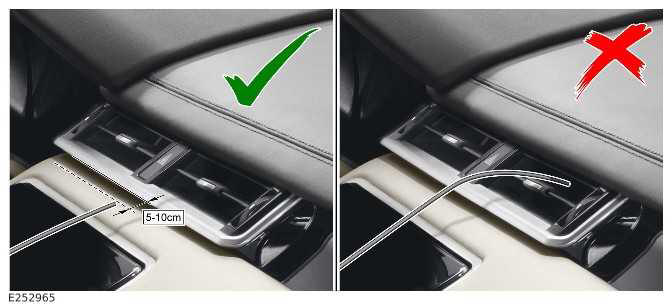

- DO NOT place the temperature sensor inside the vent as this can give a false reading

- Make sure the vehicle is in a workshop environment and not in direct sunlight

- Start the engine and run the vehicle at idle with all windows and doors closed for 30 minutes to allow the temperature to stabilize

- Set the climate control to MANUAL and FOOT and FACE distribution

- Confirm the driver and passenger temperatures are set to 22ºC

- Place the temperature sensor (Electronic Thermometer RA43230) directly

in front and in the centre (not above

or below), 5-10 cm away from the front centre vent and measure, make a note

of the temperature

- Wait for 60 seconds

NOTE: The temperature probe must be held directly in front and in the centre (not above or below) of the vent 5-10 cm away, incorrect positioning of the probe can cause up to a 4ºC temperature difference

- Place the temperature sensor (Electronic Thermometer RA43230) directly in front and in the centre (not above or below), 5-10 cm away from the rear centre face vent and measure, make a note of the temperature

- If the temperature difference is between 10ºC and 14ºC refer to the symptom chart and continue with diagnostics

- If the temperature difference is greater than 14ºC, please raise a TA case for further guidance