Land Rover Defender: Engine and Ancillaries - Removal

ENGINE AND ANCILLARIES - INGENIUM I4 2.0L PETROL

REMOVAL

SPECIAL TOOL(S)

.png)

100-012

Slide Hammer

.png)

100-012-01

Slide Hammer Adapter

.png)

JLR-303-1630

Locking Tool, Crankshaft Pulley

.png)

JLR-310-254

Injector Remover

1. Always follow the Petrol and Petrol-Ethanol Fuel Systems Health and Safety Precautions, before any repairs are done to the fuel system.

2. Raise and support the vehicle on a suitable 2 post lift.

3. Disconnect the startup battery ground cable.

4. Remove the engine assembly.

5.

.png)

- Remove the drain plug and allow engine oil to drain into a suitable container.

- Install and tighten the drain plug.

Torque: 23Nm

6.

.png)

- Remove the 3 clips.

- Remove the Noise, Vibration and Harshness (NVH) material.

7.

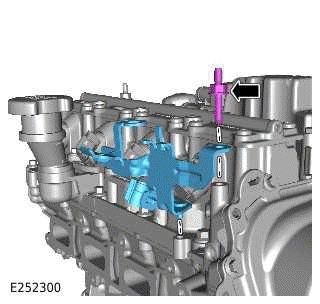

.png)

- Release the wiring harness clip.

- Remove the 2 bolts.

- Release the 2 engine coolant hose clamps.

- Remove the engine coolant pipe.

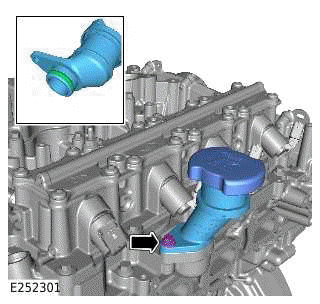

8.

.png)

- Disconnect the engine coolant pipe.

- Release the clip.

- Remove the engine coolant pipe.

9.

.png)

- Disconnect the 2 breather pipe connectors.

- Remove the breather pipe.

10.

.png)

- Remove the 2 bolts.

- Disconnect the engine coolant hose.

- Remove the engine coolant hose.

11.

.png)

- Disconnect the vacuum pipe connector.

- Release the 5 vacuum harness clips.

- Remove the vacuum harness.

12.

.png)

Remove the 2 bolts.

13.

.png)

- Disconnect the 2 electrical connectors.

- Release the 2 clips.

- Disconnect the breather pipe connector.

- Remove the purge valve assembly.

14.

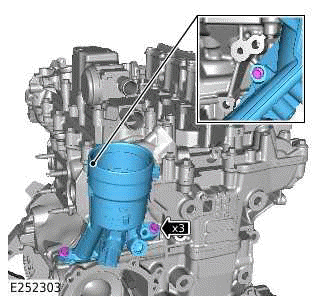

.png)

- Remove the 3 bolts.

- Release the 2 engine coolant hose clamps.

- Remove the engine coolant hose.

15.

.png)

- Release the engine coolant hose clamp.

- Disconnect the engine coolant hose.

- Remove the 3 bolts.

- Remove the engine coolant hose assembly.

- Inspect the O-ring seal. Remove and discard the O-ring seal if damaged or worn.

16.

.png)

- Release the engine coolant hose clamp.

- Release the clip.

- Remove the bolt.

- Remove the engine coolant hose.

- Inspect the O-ring seal. Remove and discard the O-ring seal if damaged or worn.

17.

.png)

- Release the engine coolant hose clamp.

- Remove the engine coolant hose.

- Inspect the O-ring seal. Remove and discard the O-ring seal if damaged or worn.

18.

.png)

- Remove the 2 bolts.

- Remove the engine coolant degas separator.

19.

.png)

- Release the 3 wiring harnesses clips.

- Remove the bolt.

- Remove the oil level gauge assembly.

- Remove and discard the O-ring seal.

20.

.png)

- Remove the 2 covers.

- Release the 2 bolts.

- Remove the 2 pulleys.

21.

.png)

- Release the clamp.

- Remove the pipe.

22.

.png)

- Reposition the cover to get access to the nut.

- Remove the nut and disconnect the startup battery cable.

- Disconnect the electrical connector.

- Release the wiring harness clip.

23.

.png)

- Remove the 2 bolts.

- Remove the generator.

24.

.png)

Disconnect the 2 electrical connectors.

25.

.png)

- Disconnect the 4 electrical connectors.

- Remove the 2 bolts.

- Release the 2 wiring harness clips.

26.

.png)

- Disconnect the 2 electrical connectors.

- Remove the 2 bolts.

27.

.png)

- Disconnect the 2 electrical connectors.

- Release the 4 wiring harness clips.

28.

.png)

- Release the wiring harness clip.

- Disconnect the 2 electrical connectors.

29.

.png)

- Disconnect the 3 electrical connectors.

- Release the 4 wiring harness clips.

30.

.png)

- Release the 8 wiring harness clips.

- Disconnect the 4 electrical connectors.

31.

.png)

- Remove the 2 nuts.

- Release the 3 wiring harness clips.

- Remove the bolt.

- Disconnect the 11 electrical connectors.

32.

.png)

- Disconnect the 2 electrical connectors.

- Release the 2 wiring harness clips.

33.

.png)

Remove the wiring harness.

34.

.png)

- Remove the 3 bolts.

- Release the 2 wiring harnesses clips.

- Remove the wiring harness.

35.

NOTE: If required, use a suitable tool to prevent the pulley from rotating.

.png)

- Remove the 3 bolts.

- Remove the engine coolant pump pulley.

36.

.png)

- Remove the 6 bolts.

- Remove the coolant pump.

- Inspect the gasket. If the gasket is damaged or worn, a new engine coolant pump must be installed.

37.

.png)

- Remove the 4 bolts.

- Remove the bracket.

38.

.png)

- Release the 2 banjo bolts.

- Remove the turbocharger oil supply pipe.

39.

.png)

- Cut and remove the 2 lower sealing washers.

- Remove and discard the 2 banjo bolts.

- Remove and discard the 4 sealing washers.

40.

.png)

- Remove the 4 bolts.

- Remove the heatshield.

41.

.png)

- Remove the bolt (1).

- Remove the and discard the bolt (2).

- Remove the heatshield.

42.

.png)

- Remove the bolt.

- Remove the heatshield.

43.

.png)

- Remove the bolt.

- Remove the turbocharger oil return pipe.

- Remove and discard the 2 O-ring seals.

44.

.png)

- Remove and discard the 4 nuts.

- Remove the turbocharger.

45.

.png)

Remove and discard the exhaust manifold gasket.

46.

.png)

- Disconnect the 2 engine coolant hose clamps.

- Remove the engine coolant hose.

47.

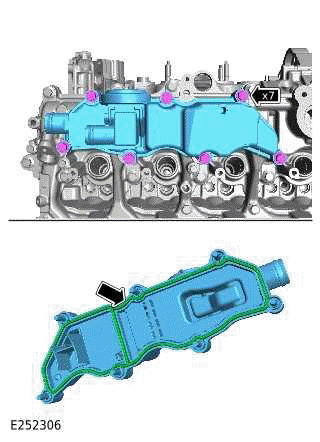

.png)

- Remove the 7 bolts.

- Remove the engine oil cooler.

- Remove and discard the gasket.

48.

.png)

- Remove the 2 bolts.

- Remove the engine coolant pipe.

- Inspect the O-ring seal. Remove and discard the O-ring seal if damaged or worn.

49.

NOTE: The bolts will remain captive.

.png)

- Release the engine coolant hose clamp and disconnect the engine coolant hose.

- Release the 7 bolts.

- Remove the intake manifold.

- Remove and discard the 4 O-ring seals.

50.

.png)

- Remove the 4 bolts.

- Remove the thermostat housing.

- Inspect the gasket. Remove and discard the gasket if damaged or worn.

51.

.png)

- Remove the 4 bolts.

- Remove the bracket.

52.

CAUTION: Fuel lines may be used a maximum of 4 times, paint mark fuel line after each full tightening sequence.

.png)

- Release the High Pressure (HP) fuel line union.

- Remove the 2 bolts.

- Remove the HP fuel line.

53.

CAUTION: Fuel lines may be used a maximum of 4 times, paint mark fuel line after each full tightening sequence.

.png)

- Release the 2 HP fuel line unions.

- Remove the HP fuel line.

54.

CAUTION: Loosen each of the bolts 1 turn at a time until the spring tension is fully released.

.png)

- Remove the 2 bolts.

- Remove the HP fuel pump.

- Inspect the O-ring seal. Remove and discard the O-ring seal if damaged or worn.

55.

.png)

Remove the HP fuel pump tappet.

56.

.png)

- Remove the 4 bolts.

- Remove the 4 ignition coils.

57.

.png)

Release the 4 wiring harness clips.

58.

.png)

- Remove the 4 bolts.

- Remove the fuel rail.

59.

.png)

- Disconnect the 4 electrical connectors.

- Remove the wiring harness.

60.

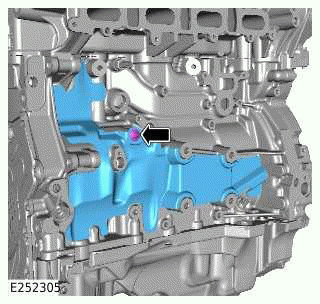

.png)

Remove and discard the 4 fuel injector spring clamps.

61.

.png)

Install the special tool.

Special Tool(s): JLR-310-254

62.

.png)

Use the special tool to remove the fuel injector.

Special Tool(s): 100-012, 100-012-01, JLR-310-254

63.

.png)

Remove and discard the fuel injector O-ring seal and washer.

64.

.png)

Remove and discard the Teflon seal.

65. Repeat steps 61 to 64 for the 3 remaining fuel injectors.

66.

.png)

- Remove the 2 bolts.

- Remove the 2 Camshaft Position Sensor (CMP) sensors.

- Inspect the 2 O-ring seals. Remove and discard the O-ring seals if damaged or worn.

67.

.png)

- Remove the 4 bolts.

- Remove the 2 variable valve timing (VVT) solenoids.

- Inspect the 2 O-ring seals. Remove and discard the O-ring seals if damaged or worn.

68.

CAUTION: Note the installed position of the component(s) prior to removal.

.png)

- Remove the bolt.

- Remove the knock sensor.

69.

CAUTION: Note the installed position of the component(s) prior to removal.

.png)

- Remove the bolt.

- Remove the knock sensor.

70.

NOTE: If equipped.

.png)

- Remove the cylinder block heater.

- Remove and discard the gasket.

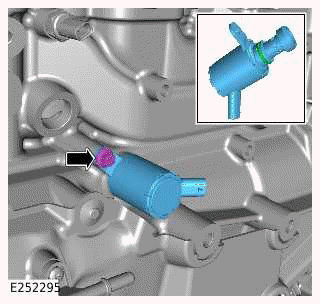

71.

- Remove the bolt.

- Remove the piston cooling oil jet solenoid.

- Inspect the O-ring seal. Remove and discard the O-ring seal if damaged or worn.

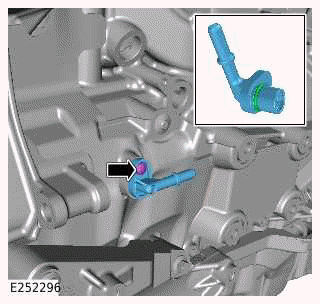

72.

- Remove the bolt.

- Remove the vacuum pipe connector.

- Inspect the O-ring seal. Remove and discard the O-ring seal if damaged or worn.

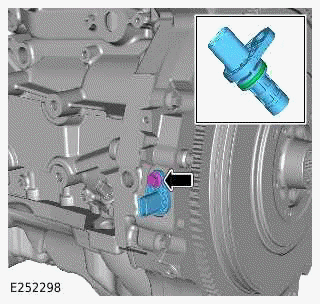

73.

- Remove the bolt.

- Remove the Crankshaft Position Sensor (CKP) sensor.

- Inspect the O-ring seal. Remove and discard the O-ring seal if damaged or worn.

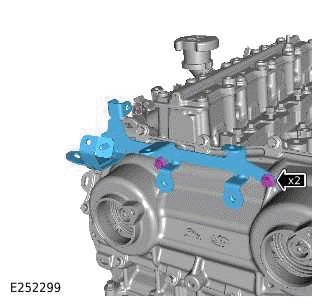

74.

- Remove the 2 bolts.

- Remove the bracket.

75.

- Remove the bracket.

- Remove the bolt.

76.

- Remove the bolt.

- Remove the oil filler.

- Inspect the O-ring seal. Remove and discard the O-ring seal if damaged or worn.

77.

- Remove the oil filter element cap.

- Remove and discard the oil filter element.

- Remove and discard the O-ring seal.

78.

- Remove the 3 bolts.

- Remove the oil filter housing.

79.

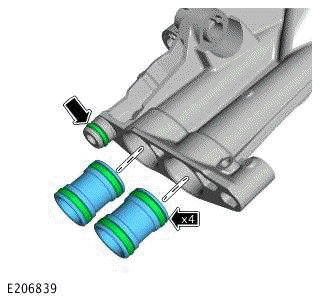

Remove and discard the 5 O-ring seals.

80.

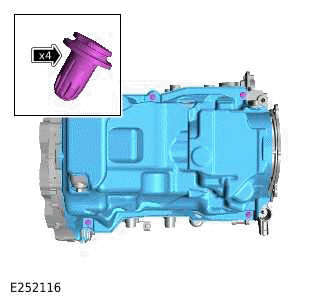

NOTE: The bolts will remain captive.

- Release the 7 bolts.

- Remove the engine vent oil separator.

- Remove and discard the gasket.

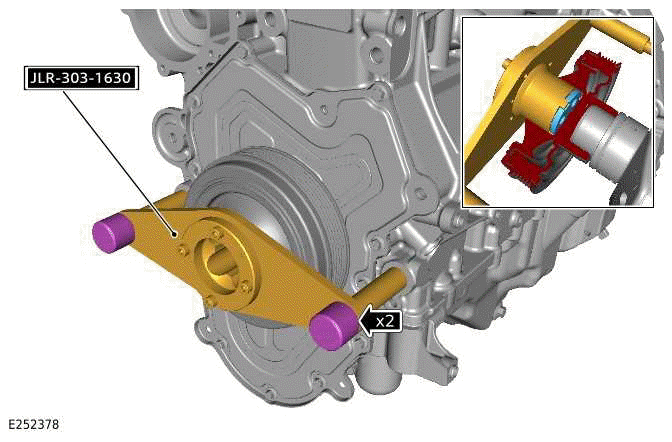

81.

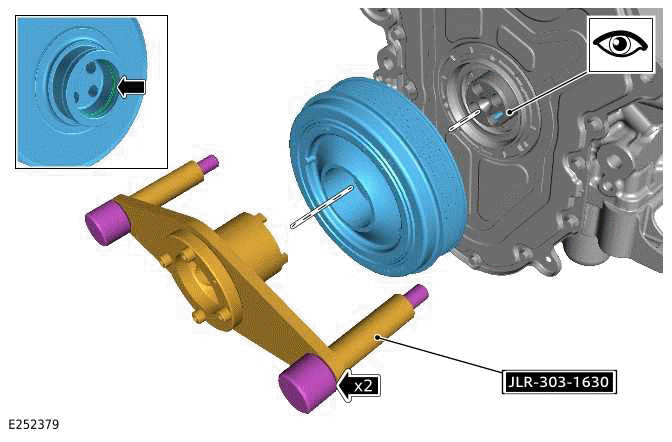

Install the special tools.

Special Tool(s): JLR-303-1630

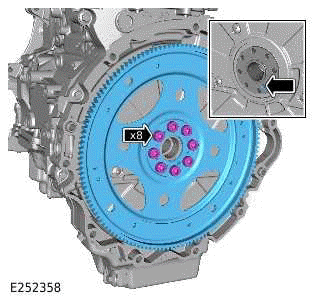

82.

- Remove and discard the 8 bolts.

- Remove the drive plate.

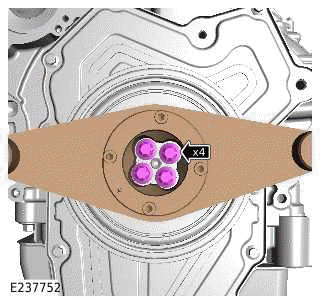

83.

CAUTION: The bolts can only be used a maximum of 4 times. Mark the bolts with a center punch. If 3 punch marks are visible, discard the bolts.

Remove the 4 bolts.

84.

- Remove the special tools.

Special Tool(s): JLR-303-1630

- Remove the crankshaft pulley.

- Inspect the O-ring seal. Remove and discard the O-ring seal if damaged or worn.

85.

- Remove the 4 clips.

- Remove the NVH material.

86.

- Remove the clip.

- Remove the NVH material.

87.

- Remove the bolt.

- Remove the NVH material.