Land Rover Defender: Engine - Diagnosis and Testing

DIAGNOSIS AND TESTING

INSPECTION, VERIFICATION AND ADDITIONAL WARNINGS FOR ELECTRIC VEHICLES

WARNINGS:

- A risk assessment must be performed before any work is undertaken. Failure to comply with this instruction may result in personal injury or death.

- All electric vehicle work must be performed by a suitably qualified person. Failure to comply with this instruction may result in personal injury or death.

- Appropriate Personal Protection Equipment (PPE) must be worn when working on or near an electric vehicle high voltage system. Failure to comply with this instruction may result in personal injury or death.

- The hybrid/EV battery pack casing must not be disassembled due to the risk of exposure to hazardous voltage. Failure to comply with this instruction may result in personal injury or death.

- The electric power inverter converter casing must not be disassembled due to the risk of exposure to hazardous voltage. Failure to comply with this instruction may result in personal injury or death.

- If the hybrid/EV battery pack is damaged or overcharged, there is a

risk of exposure to hazardous voltage

and/or highly corrosive electrolyte mist. If liquid or vapor is observed

leaking from the hybrid/EV battery

pack, take the following action:

- Evacuate the area.

- Notify manager.

- Do not breathe smoke/vapor.

- Contain spillage using spill kit.

- Wash any spillage off body and clothing (remove contaminated clothing).

- If the electric vehicle warning indicator is illuminated, the battery energy control module cannot isolate the high voltage cables. Be aware that live working will be necessary to rectify the fault. Failure to comply with this instruction may result in personal injury or death.

- Be aware that a motor generator can generate a voltage if the wheels are rotated, even if the electric vehicle system has been made safe. Failure to comply with this instruction may result in personal injury or death.

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

NOTES:

- If the control module or a component is at fault and the vehicle remains under manufacturer warranty, refer to the Warranty Policy and Procedures manual, or determine if any prior approval program is in operation, prior to the installation of a new module/component.

- When performing voltage or resistance tests, always use a digital multimeter that has the resolution ability to view 3 decimal places. For example, on the 2 volts range can measure 1mV or 2 K Ohm range can measure 1 Ohm. When testing resistance always take the resistance of the digital multimeter leads into account.

- Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

- Verify the customer concern

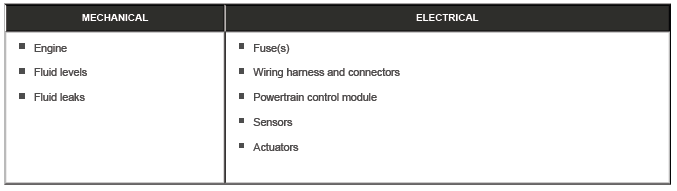

- Visually inspect for obvious signs of mechanical or electrical damage

Visual Inspection

- If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to the next step

- If the cause is not visually evident, verify the symptom and refer to the Symptom Chart, alternatively check for Diagnostic Trouble Codes (DTCs) and refer to the DTC Index

- Check the JLR claims submission system for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific customer complaint and complete the recommendations as required

READ NEXT:

Engine Oil Vacuum Draining and Filling

Engine Oil Vacuum Draining and Filling

GENERAL PROCEDURES

SPECIAL TOOL(S)

JLR-303-1644

Oil Extraction Kit

PART(S)

DRAINING

WARNINGS:

The spilling of hot oil is unavoidable during this procedure, care

must be taken to prevent scalding

Crankshaft Pulley - Ingenium I4 2.0l Petrol

Crankshaft Pulley - Ingenium I4 2.0l Petrol

REMOVAL AND INSTALLATION

SPECIAL TOOL(S)

JLR-303-1628

Remover/Installer, Front Crankshaft Seal

JLR-303-1630

Locking Tool, Crankshaft Pulley

PART(S)

REMOVAL

NOTE:

This procedure contains some vari

Crankshaft Rear Seal - Ingenium I4 2.0l Petrol

Crankshaft Rear Seal - Ingenium I4 2.0l Petrol

REMOVAL AND INSTALLATION

SPECIAL TOOL(S)

100-012

Slide Hammer

JLR-303-1674

Installer - Rear Crankshaft Oil Seal

JLR-303-1674A

Installer - Rear Crankshaft Oil Seal

JLR-303-1712

Remover, Rear Cranks

SEE MORE:

Anti-Theft - Passive - Component Location, Overview

Anti-Theft - Passive - Component Location, Overview

COMPONENT LOCATION

COMPONENT LOCATION - 1 OF 4

NOTE:

Right Hand Drive (RHD) vehicle is shown, Left Hand Drive (LHD) vehicle is

similar.

Immobilizer Antenna Unit (IAU)

Ignition switch

Body Control Module (BCM)/ Gateway Control Module (GWM)

COMPONENT LOCATION - 2 OF 4

NOTES:

RHD vehicle is sh

Tire glossary

Tire glossary

lbf/in² or psi: Pounds per square inch, an

imperial unit of measure for pressure.

kPa: Kilopascal, a metric unit of measure

for pressure.

Cold tire pressure: The air pressure in a

tire which has been standing in excess of

3 hours, or driven for less than 1 mile.

Maximum permissible inflation pre

© 2010-2025 Copyright www.lrdefender.org